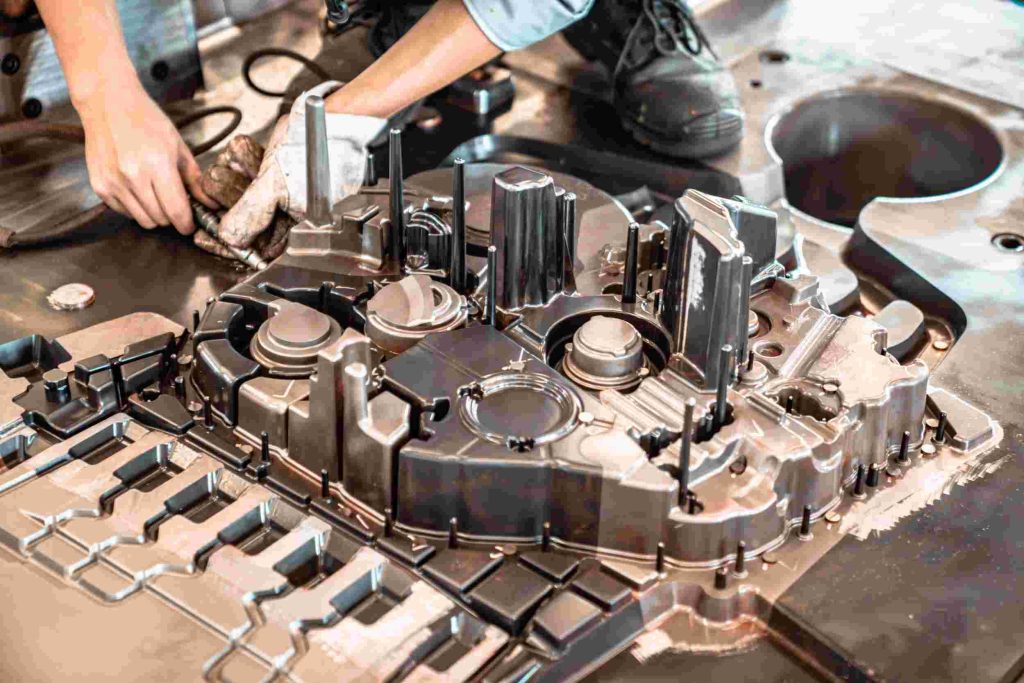

Durability grows through controlled shaping that forms strong parts, and this process supports steady performance across many uses. Many creators choose efficient shaping processes for long-lasting parts because they offer strength with dependable consistency. These parts stay firm through stress, which supports long-term use without early damage. The high pressure die casting vietnam helps create strong pieces that hold shape under load, which brings a steady outcome for many applications. Here, we notice helpful points that guide makers toward reliable shaping that supports longer use without wasting effort.

How does this process improve strength?

Careful shaping builds firm structures that hold pressure with consistent support, which keeps parts steady through repeated use for longer service.

Why does controlled flow support uniform parts?

Constant flow fills every space, which forms solid pieces that stay firm without weak gaps which supporting steady function through long working cycles.

What makes surface quality important

Smooth outer layers reduce early wear, which keeps pieces stable, which supports longer use through repeated movement without early breaks or cracks.

How does pressure aid material bonding?

Strong pressure binds material tightly, which keeps pieces unified without loose points, which supports stable performance through tough working phases.

Why is heat balance needed?

Balanced heat keeps the material stable, which prevents stress damage and supports parts that stay firm through many working conditions.

How does shaping speed matter

Fast shaping locks the material evenly, which forms tough pieces without weak spots which supporting constant use without early distortion.

What helps reduce unwanted stress

Controlled cooling reduces strain, which keeps pieces from bending, which supports a firm structure through long-running cycles without shape loss.

How does accuracy support longer use?

Accurate shaping forms balanced parts that hold steady under load, which supports long life through repeated cycles without structural weakness.

What supports stable thickness

Even walls keep pressure balanced, which prevents cracks and supports strong pieces that stay firm through extended working phases.

Why is finishing treated as important

Refined finishing removes tiny edges, which prevents early damage, and supports long working use without rough wear or slow weakening.

Stronger shaping supports long use through stable parts that stand firm through repeated pressure without early wear. Makers gain value through consistent shaping that stands through many conditions without frequent changes. Solid pieces hold their form, which helps reduce waste while supporting steady use. Balanced shaping keeps every part unified, which protects against early faults. Reliable shaping brings durable items that last through heavy work. The high pressure die casting vietnam helps makers find stable outcomes through controlled shaping that protects long-running performance.