The world of machines alongside automation depends totally on precision. Ball screws serve as essential components that ensure smooth accurate movement of machine parts. The Ball Screw SDA-V represents one of the most sophisticated types of ball screw systems since it operates in numerous machines to drive precise and effective movement.

The device requires explanation alongside its critical nature. The following explanation simplifies the understanding of this subject.

What is a Ball Screw SDA-V?

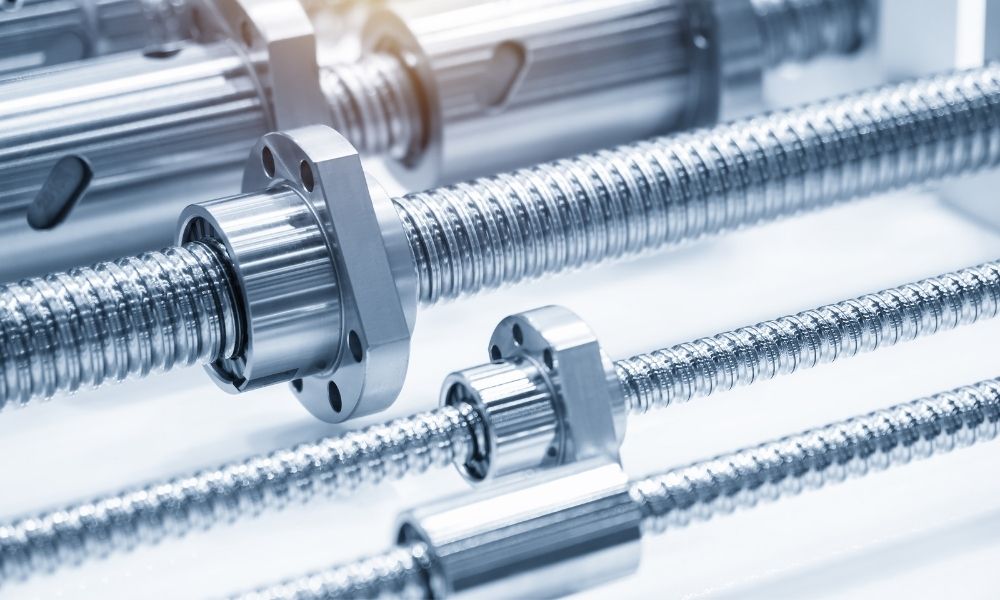

The Ball Screw SDA-V operates as a mechanical system that turns rotational motion into linear motion. The device transforms rotational movements into exact straight-line motions. The Ball Screw SDA-V functions through the combination of a screw and nut and ball bearings that minimise friction and enable smooth operation. Ball screws operate by using small rolling balls that enable their fast and durable motion, unlike traditional screws.

Why is it Used in Machines?

Most machines need accurate and regulated motion operations. The Ball Screw SDA-V [บอลสกรู SDA-V, which is the term in Thai] operates in CNC machines as well as industrial robots and factory automation systems and 3D printers. The machine requires precise linear movement of parts with no extra resistance or friction so ball screws become essential to this process. The smooth movement of ball screws decreases machine wear thus machines operate efficiently with extended service life.

When the screw rotates, the ball bearings inside roll between the screw and the nut. The rolling motion between the components minimises friction which enables the machine to move smoothly without losing energy.

The Ball Screw SDA-V design enables faster movement with higher precision than lead screws because it rolls rather than slides. The smooth operating condition allows machines to waste less energy which makes ball screw SDA-V an efficient choice for movement.

Advantages of Ball Screw SDA-V

This ball screw stands out because it provides superior accuracy to its users. The system guarantees precise movement of machines by eliminating all possible delays and mistakes. The ball screw delivers smooth and effortless movement because of its low friction properties.

The low friction operation extends the lifespan of the screw beyond what standard screws can achieve. The preloaded nut feature of certain versions eliminates backlash thus providing better control precision.

Final Thoughts

Modern machines need the Ball Screw SDA-V as their fundamental element to achieve precise and fast operations while maintaining high-efficiency standards. The tool provides significant value for various applications by transforming rotational movement into linear motion. This ball screw maintains machines in smooth operation through accurate and efficient performance because of its advanced design and high durability.