In today’s fast-paced manufacturing landscape, the demand for high-quality, precision-engineered components is at an all-time high. From automotive to aerospace and electronics, industries are continually seeking solutions that guarantee reliability and performance. One such solution that has revolutionized precision engineering is CNC turned components. These components play a pivotal role in driving the efficiency and precision of modern machinery, offering numerous advantages over traditional manufacturing methods.

What are CNC Turned Components?

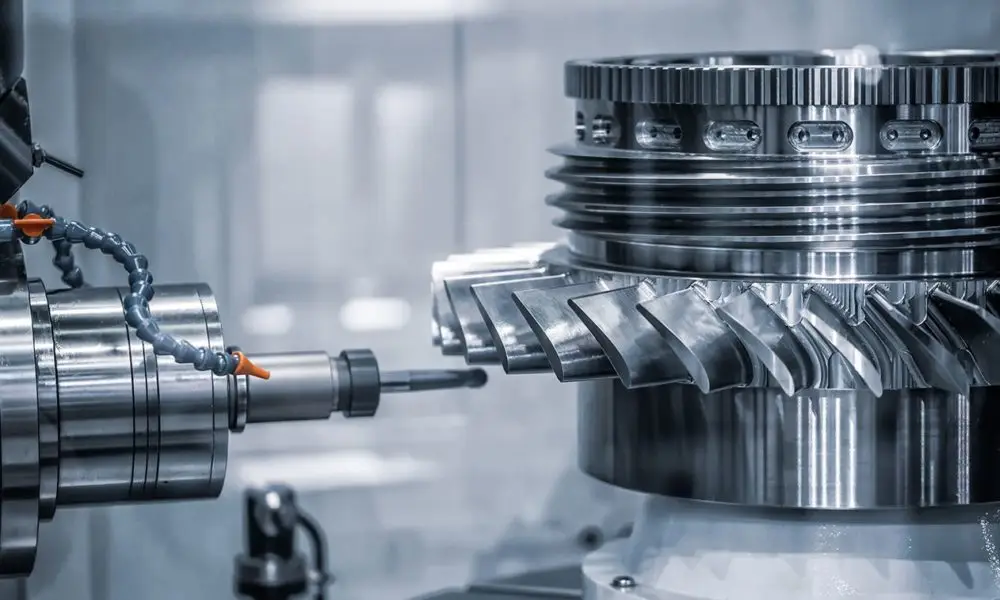

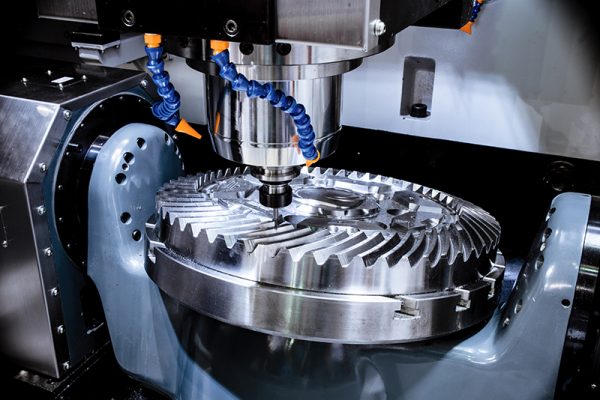

CNC turning is a highly efficient manufacturing process that utilizes computer numerical control (CNC) machines to create precise and complex components. The process involves rotating a workpiece against a cutting tool to achieve the desired shape. CNC turning allows manufacturers to create parts with exceptional accuracy, reducing human error and ensuring repeatability. These parts, often referred to as CNC turned components, are used in a wide range of industries, from automotive and electronics to medical and aerospace applications.

The Role of CNC Turned Parts in Precision Manufacturing

The precision and quality achieved through CNC turning are unmatched, making it a preferred choice for high-precision industries. Whether it’s producing CNC components for complex machinery or manufacturing CNC auto parts, the accuracy and repeatability offered by CNC turning technology ensure optimal performance and functionality. CNC turned parts suppliers play a crucial role in meeting the ever-growing demand for these components, offering solutions tailored to the unique needs of various industries.

In the automotive sector, for instance, CNC turning parts are used to manufacture critical components such as engine parts, shafts, and fittings. These components must meet stringent quality standards to ensure the safety and performance of the vehicle. The precision offered by CNC turning helps eliminate defects, ensuring that each part is identical and fits perfectly into the assembly line. This level of consistency is especially important for CNC auto parts manufacturers, who rely on precision to meet industry specifications.

Why Choose CNC Turned Components?

The growing demand for high-quality, reliable parts in precision industries has made CNC turned components a go-to solution for manufacturers. These components offer several advantages, including:

- Superior Accuracy: CNC turning ensures that components are produced to exact specifications, offering unmatched precision.

- Consistency and Repeatability: With CNC machines, manufacturers can produce identical parts in large volumes, reducing variations and errors.

- Cost-Effectiveness: While initial setup costs for CNC machines can be high, the long-term cost savings due to reduced labor and material waste make it a highly cost-effective manufacturing solution.

- Versatility: CNC turning can be used to manufacture a wide range of components, from simple parts to complex, intricate designs.

The Future of CNC Turning in High-Precision Industries

As industries continue to evolve, the demand for CNC turned components will only increase. The capabilities of CNC machines are expanding, with advancements in software, tooling, and automation pushing the boundaries of what’s possible. The ability to create highly intricate parts with tight tolerances will continue to redefine quality standards across sectors, ensuring that CNC manufacturers in India and around the world stay at the forefront of innovation.

Moreover, as industries such as aerospace and medical technology require more specialized components, the role of CNC turned parts suppliers becomes even more critical. These suppliers must not only provide high-quality parts but also offer personalized solutions that cater to the unique requirements of each application.

“The rise of CNC turning parts has undoubtedly reshaped the way industries approach manufacturing, offering unprecedented levels of accuracy, efficiency, and versatility. As high-precision industries continue to grow, CNC turned components will remain integral to maintaining quality standards and meeting the demands of modern technology.

For companies seeking top-tier CNC turned components, it’s essential to partner with experienced and reliable suppliers. With a focus on innovation and precision, CNC turning is set to lead the charge in manufacturing excellence.

Ganesh Precision, a leading CNC manufacturers in India, is committed to providing high-quality, precision-engineered CNC turned components to industries across the globe. Whether you’re looking for CNC auto parts manufacturers or CNC turned parts suppliers, Ganesh Precision offers the expertise and advanced technology to meet your needs.”